Unused Atex Graphite Dense Phase Conveying & Blending System

Specifications

| Stock Number | 9740 |

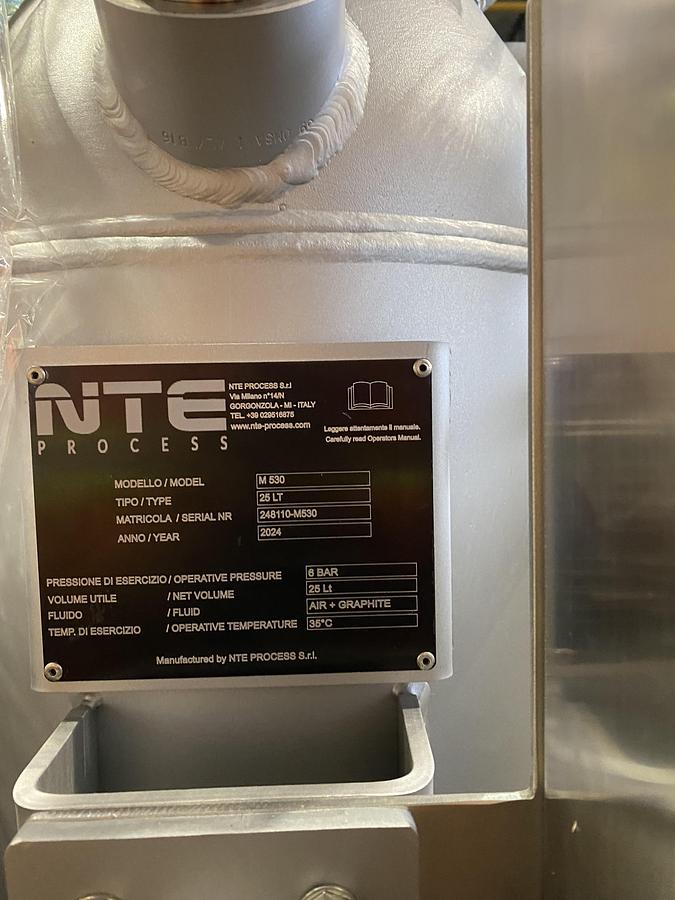

| Manufacturer | NTE Process |

| Year | 2024 |

Description

3,000 KG Batch – 500 KG/H – Explosion Rated – Stainless Steel – PED Certified

Overview

Unused, engineered dense phase pneumatic conveying and blending system originally designed for ultra-fine graphite powder in a classified explosion safety zone.

This is not a general-purpose powder system. It was custom-engineered for:

- Fine particle size (5–50 µm)

- Low bulk density material (0.34–0.58 kg/dm³)

- Ultra-low moisture (<0.1%)

- Explosion-risk environment

- Controlled dense-phase transfer

- Pressure-assisted blending

Original new cost: $389,088 CAD

System has never been commissioned.

SYSTEM APPLICATION

Designed specifically for:

• Graphite

• Carbon black

• Battery materials

• Fine minerals

• Conductive powders

• Explosion-sensitive dust

Ideal for operations requiring:

✔ Dense phase conveying

✔ Controlled low-velocity transport

✔ Dust cloud minimization

✔ ATEX / explosion safety compliance

✔ Homogeneous batch blending

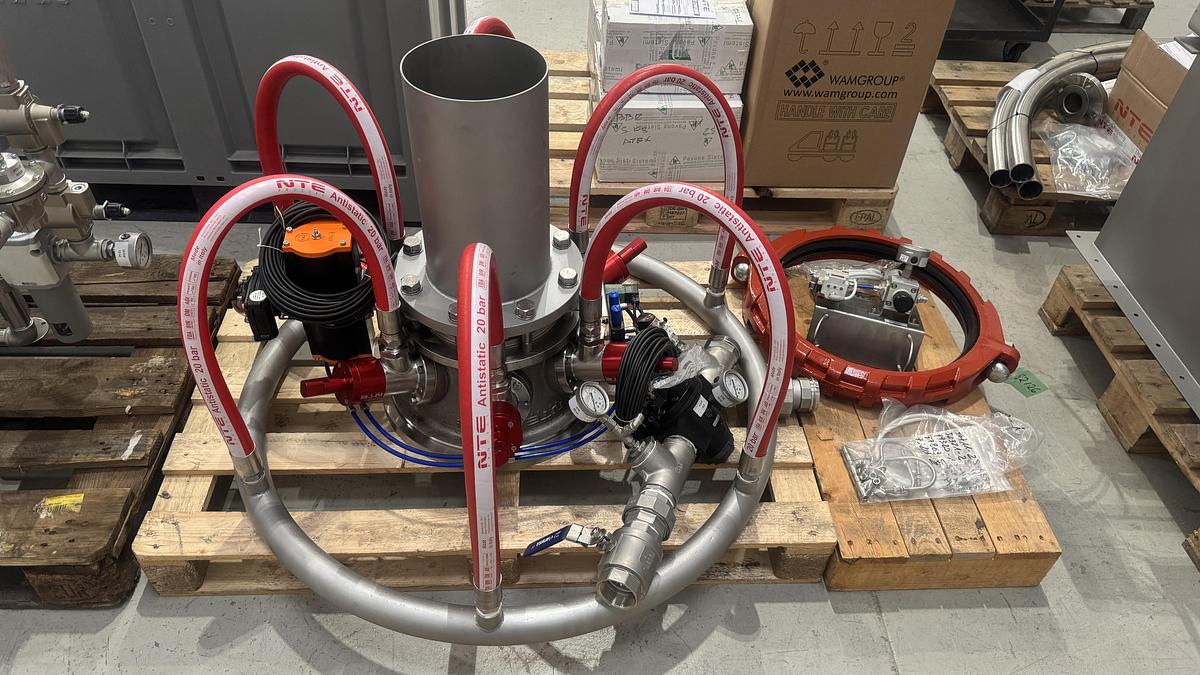

SYSTEM 100 – SMART JET DENSE PHASE CONVEYOR

Smart-Jet M530 – 60L Pressure Vessel

- Stainless Steel AISI 304 construction

- Useful capacity: 60 liters

- PED 2014/68/EU certified pressure vessel

- Working pressure: 1–2 bar

- Designed for explosion-risk zones

- 2" conveying line

- Capacity: 500 kg/hour

- Convey distance: 15 meters

- 3 x 90° bends (estimated)

Equipped With:

• DN150 inlet butterfly valve with pneumatic actuator

• Solenoid valve and limit switches

• Internal FluiDisk system

• Interchangeable outlet insert

• Pressure regulator with gauge

• Volume control valve

• Air control solenoid valve

Air Requirements (Conveying Mode)

• Surge Air: 200 Nm³/h

• Average Air: 50 Nm³/h

Dense phase conveying significantly reduces:

✔ Particle degradation

✔ Dust generation

✔ Static ignition risk

✔ Pipeline wear

SYSTEM 200 – 3,000 KG BLENDING HOPPER

Stainless Steel AISI 304 Construction

- Water capacity: 16 m³

- Cylinder diameter: 2200 mm

- Cylinder height: 4000 mm

- Overall height: 5400 mm

- 60° cone slope (engineered for anti-ratholing)

- Discharge flange: 300 mm

- DN200 inlet

- DN600 filter connection

- Hopper support brackets

- Threaded connection for level switch

Pressure-Assisted Blending Specifications

Designed for fluidized air pulse blending:

• Batch size: 3,000 kg

• Blend pressure: 1.7 barg

• Pulse ON time: 1 second

• Pulse OFF time: 1 second

• Estimated cycle time: 40 minutes per batch

Air Requirements (Blending Mode)

• Surge Air: 600 Nm³/h

• Average Air: 400 Nm³/h

System is engineered for uniform blending of fine, low-density, cohesive powders without mechanical agitators.

ENGINEERING FEATURES

✔ Explosion-risk design

✔ Antistatic pneumatic components

✔ Pulse-jet blending system

✔ Pressure-rated vessel construction

✔ Stainless steel fabrication

✔ Structural support frame

✔ Automated valve controls

✔ Industrial pneumatic solenoid system