Used Dilute Phase Vacuum Conveying System

Caractéristiques

| Numéro de stock | 9178 |

Description

Dilute Phase Vacuum Conveying System - Convey up to 3,000lb/hr

· One (1) vacuum filter/receiver with the following features:

· Type 304 stainless steel construction

· Nominally 38” Diameter x 7’-6-1/2” overall height

· Seven (7) 8” Diameter x 36” long filter cartridges with “open-pleat” design for effective release

· Total filter area is 209.3 ft2 at 99.9% efficient at 0.5 microns, 5:1 air-to-cloth ratio and 135.9 fpm can velocity

· One (1) 18” x 24” service access door for side-loaded filter media

· Three (3) pulse valves with remote pilot solenoids

· One (1) NEMA 4X, 120V timing controller

· One (1) pressure gauge/transmitter for differential pressure indication

· One (1) pressure switch for initiation of pulse on demand filter cleaning

· One (1) filter/regulator for compressed air supply

(5 SCFM of compressed air required).

· One (1) level switch (paddle type) 24 VAC, NEMA 4X

· Set of support lugs

· Support frame

· Interior finish will be #4 (no pits or crevices) welds continuous and ground with 80 grit, tape-striped and buffed

· Exterior finish will be #2B with welds tape-striped and buffed to remove discoloration

· Five (5) 8” Diameter drop-thru rotary airlock valves (food-grade, non-sanitary) for pack and blend tank discharge. Each with 0.57 kW (0.75 HP) 3ph-60 Hz-575V gearmotors

· One (1) 8” Diameter drop-thru rotary airlock valve with 0.57 kW (0.75 HP) 3ph-60Hz-575V gearmotor for the vacuum filter/receiver powder outlet

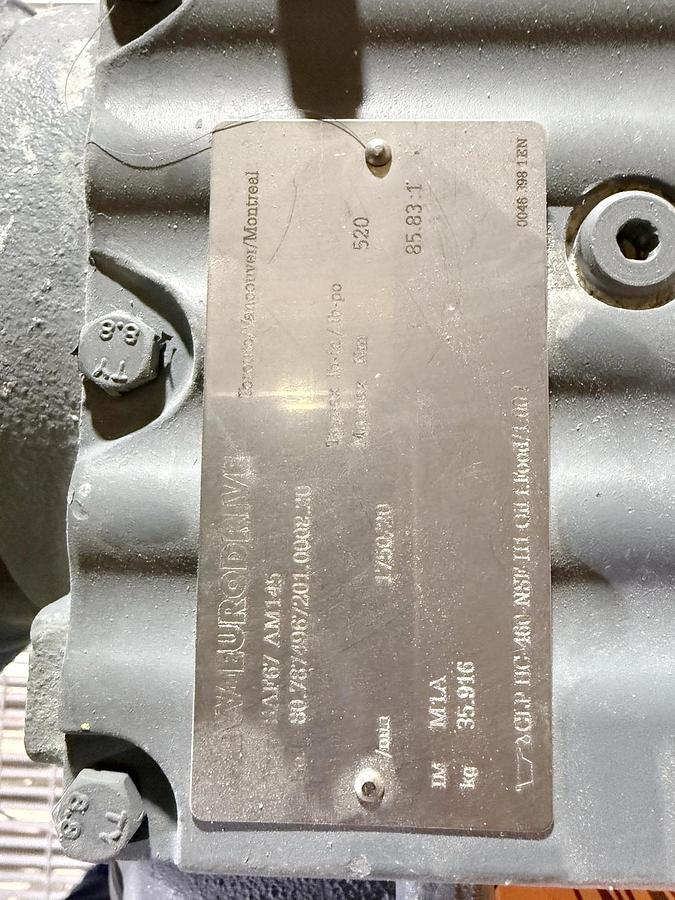

· One (1) vacuum producer, Sutorbilt P.D. blower (rotary lobe type) with the following features:

· One (1) 20 HP TEFC, 575V-3ph-60Hz premium efficiency motor

· One (1) heavy duty cast and machined casing

· One (1) dual lobe type steel impeller

· One (1) structural steel base, powder coated

· One (1) custom tuned silencer for exhaust

· One (1) exhaust air check valve

· One (1) automatic vacuum relief set at 8” Hg

· One (1) vacuum gauge

· One (1) Inline filter 99% @ 10-micron efficiency

· One (1) pressure gauge across filter

· One (1) pressure switch across filter, 110V, NEMA 7

· Sound Enclosure for Vacuum Blower:

o Material of construction: Aluminum

Overall dimensions (nominal): 44” wide x 78” long x 90” tall (top of vent fan hood)

3” thick acoustic foam sound insulation lining inside of enclosure, all around (walls, doors, ceiling)

Ventilation fan with 1/4 HP, 575V, 3ph, 60 Hz motor

· Complete set of 4” OD convey line with:

· Five (5) powder pick-up tees (mounted to each pack tank)

· Up to 120 feet of straight tube (80 feet horizontal, 40 feet vertical)

· Two (2) standard radius elbows (6” CLR)

· Two (2) long-sweep elbows (24” CLR)

· Up to (15) “Morris” compression couplings (3-bolt type)

· Set of riser clamps and pipe hangers

· All stainless steel, mill finish

· One (1) supply air HEPA filter and housing

· Complete set of controls and integration

Location: Winnipeg, Manitoba